In today’s travel and lifestyle accessories market, the toiletry bag (also known as a dopp kit) remains one of the most commercially reliable products for brands. It’s compact, functional, highly customizable, and suitable for private label, OEM, and ODM production.

But for brand owners, designers, and sourcing managers, “how to make a simple toiletry bag” is not just a DIY question—it’s a manufacturing decision.

Solton Leather as a leather goods supplier with years of experience producing toiletry bags for global brands, we’ll walk you through the real manufacturing process behind a simple toiletry bag—from materials and construction to sizing, cost considerations, and customization options.

Whether you’re developing your first product or optimizing an existing line, this guide is written from a factory-side perspective, not a hobbyist one.

For brands looking to scale production, working with a reliable custom toiletry bag manufacturer is far more effective

Why Simple Toiletry Bags Are a Smart Product for Brands

From a manufacturing standpoint, simple toiletry bags offer several strategic advantages:

Low development risk (simple structure, stable demand)

Flexible materials (PU, leather, recycled fabrics, waterproof textiles)

Short sampling time

Scalable production from small MOQ to bulk orders

Strong gifting & travel use cases

For many DTC and retail brands, toiletry bags are often:

Entry-level products

Add-on items for bundles

Seasonal promotional SKUs

Corporate or gift-with-purchase items

Step 1: Define the Purpose Before Making a Toiletry Bag

Before cutting any material, manufacturers always start with one key question:

What is this toiletry bag designed for?

Because usage determines structure, material, and cost.

Common use cases include:

Daily bathroom essentials

Travel grooming kits

Hotel amenities or airline kits

Luxury men’s grooming products

Waterproof cosmetic storage

For example:

A travel toiletry bag usually requires lining + durability

A luxury leather dopp kit focuses on material quality and stitching

A promotional toiletry bag prioritizes cost control and fast production

Defining this early prevents redesigns and cost overruns later.

Step 2: Choosing the Right Materials to Make a Simple Toiletry Bag

Common Toiletry Bag Materials Used in Manufacturing

1. PU Leather

Cost-effective

Consistent texture

Easy logo embossing

Suitable for mid-range brands

2. Genuine Leather (Cowhide / Top Grain / Full Grain)

Premium positioning

Strong durability

Natural texture variation

Higher unit cost, higher perceived value

3. Waterproof Fabric (Nylon / Polyester / TPU-coated)

Lightweight

Travel-friendly

Easy cleaning

Ideal for outdoor or sporty brands

4. Recycled or Sustainable Materials

Growing demand in EU & US markets

Requires verified sourcing

Often paired with sustainability messaging

👉 Manufacturer tip:

Material thickness directly affects sewing difficulty, zipper lifespan, and bag structure. Always test samples before final approval.

Table 1: Toiletry Bag Material Comparison (For Brands & Manufacturers)

| Material | Cost Level | Durability | Water Resistance | Best For |

|---|---|---|---|---|

| PU Leather | Low–Medium | Medium | Medium | Private label brands, promotional toiletry bags |

| Genuine Leather | Medium–High | High | Low–Medium | Premium & luxury toiletry bags |

| Nylon / Polyester | Low | Medium | High | Travel and outdoor toiletry kits |

| Recycled Fabric | Medium | Medium | Medium | Sustainable and eco-conscious brands |

Step 3: Standard Sizes for a Simple Toiletry Bag

While toiletry bags can be fully customized, most manufacturers follow proven size ranges to reduce production risk.

Popular toiletry bag sizes:

Small: 20 × 8 × 10 cm

Medium (most common): 24 × 10 × 14 cm

Large / Travel: 26 × 12 × 16 cm

Choosing standard dimensions helps:

Optimize cutting efficiency

Reduce material waste

Control carton packing costs

Speed up sample development

Table 2: Common Toiletry Bag Sizes Used in Manufacturing

| Size Category | Dimensions (cm) | Capacity | Typical Use Case |

|---|---|---|---|

| Small | 20 × 8 × 10 | Minimal | Daily essentials, gift sets |

| Medium (Most Popular) | 24 × 10 × 14 | Standard | Travel toiletry bags, retail products |

| Large | 26 × 12 × 16 | High | Long trips, grooming kits |

Step 4: Pattern Making – The Foundation of Quality

In manufacturing, pattern design matters more than appearance.

A simple toiletry bag usually includes:

Main body panels

Side panels (or folded gussets)

Lining pattern

Zipper allowance

Reinforcement areas

Experienced factories design patterns with:

Seam tolerance

Material shrinkage

Sewing order efficiency

Zipper curve control

A poorly designed pattern leads to:

Uneven shape

Difficult zipper installation

Higher defect rate in mass production

Step 5: Cutting & Preparation

Once patterns are confirmed:

Materials are cut manually or by machine

Lining and shell are prepared separately

Reinforcement layers are added where needed

Zippers and hardware are pre-matched

For leather toiletry bags, grain direction and leather flaws must be considered during cutting to ensure consistency.

Step 6: Sewing & Manufacturing Process

A basic toiletry bag sewing sequence includes:

Stitch shell panels

Install zipper

Attach side gussets

Sew lining

Combine shell and lining

Turn bag and shape

Final topstitching

This is where experienced workers make a real difference.

Clean stitching, even tension, and zipper alignment define perceived quality.

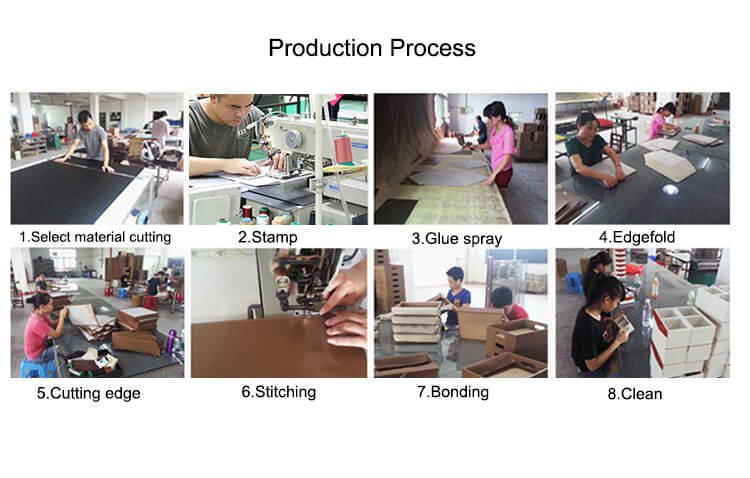

Manufacturing Flow: Simple Toiletry Bag Production

- Step 1: Pattern confirmation & material inspection

- Step 2: Material cutting (shell & lining)

- Step 3: Zipper installation

- Step 4: Sewing main panels & gussets

- Step 5: Lining attachment

- Step 6: Shape forming & top stitching

- Step 7: Quality control & packing

Step 7: Quality Control in Toiletry Bag Production

From a factory perspective, QC is not optional.

Typical quality checks include:

Zipper smoothness test

Stitch density consistency

Shape symmetry

Logo position accuracy

Material surface inspection

For B2B orders, pre-shipment inspection reduces return risk and protects brand reputation.

Step 8: Customization Options for Private Label Brands

One of the biggest advantages of toiletry bags is customization flexibility.

Common Custom Options

Logo: embossing, debossing, metal plate, printing

Lining color & pattern

Zipper type & puller

Handle or side strap

Packaging (dust bag, gift box, polybag)

👉 OEM insight:

Simple structure + customization = high perceived uniqueness with controlled cost.

Custom leather toiletry bags produced for private label brands

Step 9: Cost Factors You Should Know Before Production

Many brands ask: “Why do prices vary so much for the same toiletry bag?”

Main cost drivers include:

Material type & thickness

Lining quality

Zipper brand

Stitching complexity

Order quantity (MOQ)

Packaging requirements

Reducing cost doesn’t mean lowering quality—it means designing smarter with the factory.

💰 Table 3: Key Cost Factors in Toiletry Bag Manufacturing

| Cost Element | Impact Level | Notes from Manufacturer |

|---|---|---|

| Main Material | High | Leather thickness and quality directly affect unit cost |

| Lining | Medium | Waterproof lining increases cost slightly |

| Zipper & Hardware | Medium | YKK or custom pullers raise perceived value |

| Labor | Medium | Complex stitching increases labor time |

| Order Quantity | High | Higher MOQ significantly reduces unit price |

Step 10: From Sample to Bulk Production

A professional toiletry bag manufacturer typically follows this timeline:

Sample development: 5–7 days

Sample revisions: 3–5 days

Bulk production: 25–35 days

QC & packing: 3–5 days

Clear communication during sampling saves weeks later.

Common Mistakes Brands Make When Developing Toiletry Bags

From years of manufacturing experience, these are the most common issues:

Overcomplicated design for a simple product

Ignoring lining and zipper quality

Choosing material without testing durability

Skipping pre-production samples

Focusing only on price, not consistency

A “simple” toiletry bag still requires professional execution.

Why Work with an Experienced Toiletry Bag Manufacturer

For B2B buyers, the right manufacturing partner should:

Understand your target market

Advise on material and structure

Control quality at every step

Support OEM & private label needs

Scale with your business

At Solton Leather, we help brands turn simple toiletry bag ideas into repeatable, scalable products, not one-off samples.

FAQ – Toiletry Bag Manufacturing Questions

Q1: What is the best material for a toiletry bag?

It depends on your market positioning. PU for cost control, genuine leather for premium brands, waterproof fabric for travel-focused use.

Q2: Can I customize a toiletry bag with my brand logo?

Yes. Most factories offer embossing, metal logos, or printing options.

Q3: What is the MOQ for custom toiletry bags?

MOQ usually starts from 100 pcs, depending on material and customization.

Q4: How long does production take?

Samples: 5–7 days. Bulk orders: 25–35 days.

Q5: Are toiletry bags suitable for private label brands?

Absolutely. They are one of the easiest and most reliable private label products.

Q6: Is learning how to make a simple toiletry bag useful for brands?

Understanding how to make a simple toiletry bag helps brands communicate better with manufacturers, optimize design decisions, and control production costs.

Final Thoughts: Simple Design, Professional Manufacturing

Making a simple toiletry bag is not about complexity—it’s about precision, materials, and execution.

For brands, the real value comes from working with a manufacturer who understands both design intent and production reality.

Knowing how to make a simple toiletry bag is not about sewing skills, but about making smarter manufacturing decisions.