Crossbody bags have become one of the most stable and profitable product categories in the global accessories market. From fashion and lifestyle brands to corporate gift buyers and private label retailers, demand for custom crossbody bags continues to grow in the US, EU

Southeast Asia and Australia,South America,North America markets.

However, success doesn’t come from choosing the cheapest supplier, but from partnering with the right custom crossbody bag manufacturer – one that understands materials, construction, branding, and B2B production standards.

This guide is designed for brands, importers, wholesalers, and purchasing managers who want to confidently develop or expand their crossbody bag product line.

Why Crossbody Bags Are a Core Product for Global Brands

Crossbody bags are a rare combination of functionality, versatility, and commercial viability.

Compared to handbags or backpacks, crossbody bags:

- Free up your hands for daily use

- Are suitable for a wide range of consumer groups (fashion, travel, outdoor, business)

- Are suitable for both men’s and women’s collections

- Are easily adaptable to different materials and price range

For B2B buyers, crossbody bags mean:

- Lower development risk

- Faster market entry

- Higher repurchase rate

That’s why many brands start their handbag collections with crossbody bag styles.

What a Custom Crossbody Bag Manufacturer Does for Your Brand

A professional custom crossbody bag manufacturer is not just a factory. They act as a production partner throughout the entire development process, including:

- Bag structure and pattern development

- Material sourcing and testing

- Sample making and modifications

- Mass production and quality control

- Packaging, labeling, and shipment delivery

Unlike trading companies, a true manufacturer controls production internally, which leads to:

- More stable product quality

- Better cost transparency

- Faster sample making and production response speed

This level of control is most important for brands focused on long-term growth .

Popular Types of Custom Crossbody Bags for OEM & Private Label

Before contacting manufacturers, brands should clearly define their product direction.

Common B2B crossbody bag styles include:

Minimalist leather crossbody bags for fashion brands

Nylon or canvas crossbody bags for streetwear and outdoor labels

Anti-theft crossbody bags for travel brands

Utility-style crossbody bags for men’s accessories

Premium crossbody bags with metal hardware for luxury collections

A capable crossbody bag OEM manufacturer will help you refine the following as below:

Bag size and scale

Internal compartments

Strap width, length, and comfort

- Colors and material options

- metal hardware options

Materials Used by Professional Crossbody Bag Manufacturers

Material choice directly affects cost, durability, and brand positioning.

Common materials include:

Genuine leather: full-grain, top-grain, split leather

PU / vegan leather: cost-effective and consistent,Design Flexibility

Nylon / polyester: lightweight and water-resistant

Canvas: casual appearance with eco-friendly appeal

- eco-friendly leather:Durable & Practical,and recyclable.

An experienced manufacturer will:

Provide material swatches to choose

Explain material durability and used features

Recommend alternatives based on your target price

Customization Options You Should Expect from a Crossbody Bag Manufacturer

Customization is a core value of OEM and ODM manufacturing.

Standard customization options include:

Bag dimensions and internal layout

Strap design and attachment method

Zippers, buckles, and metal accessories

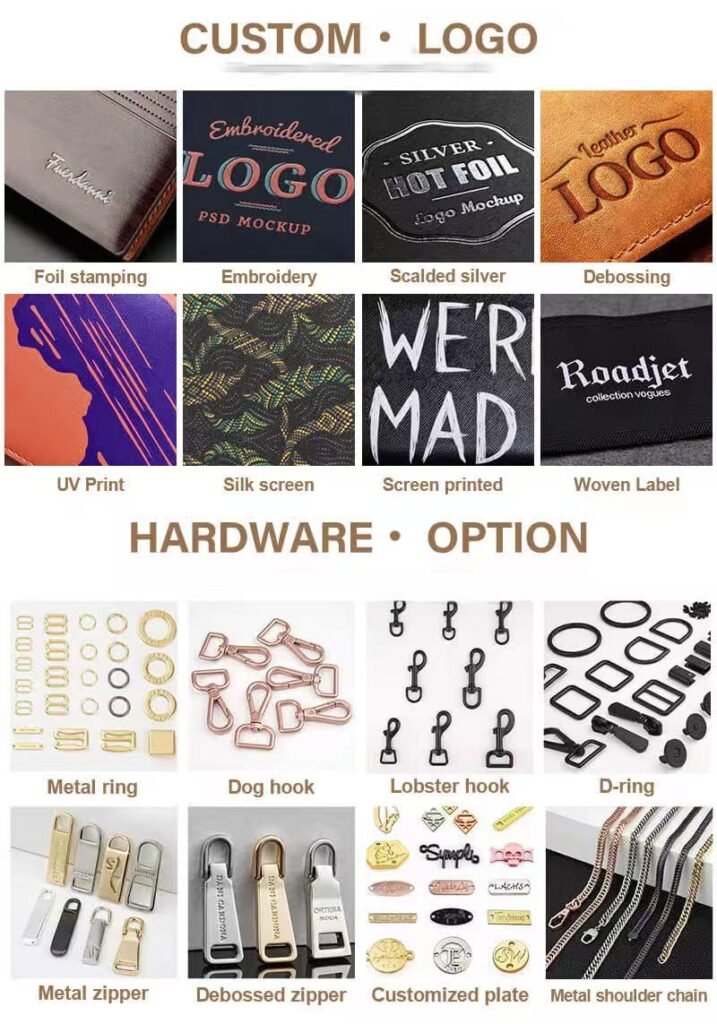

Logo application (embossed, debossed, metal plate, printing)

Lining fabric and stitching details

As a Professional manufacturers will also provide advice on:

Which details significantly increase cost

Which designs affect production lead time

how to reduce defect rates

OEM vs ODM: Working with a Custom Crossbody Bag Manufacturer

Understanding OEM and ODM can helps you avoid costly mistakes.

OEM (Original Equipment Manufacturer)

You provide design or reference

The factory manufactures according to the specifications.

Best for established brands

ODM (Original Design Manufacturer)

Factory provides base designs

You customize materials and branding

Ideal for startups or fast product launches

OEM & ODM explained in detail:

MOQ, Pricing, and Lead Time Explained

For leather crossbody bags, many brands prefer starting with 200–300 pieces to balance cost and market testing.

MOQ depends on:

Material type

Bag complexity

Custom hardware requirements

Typical ranges:

PU or fabric crossbody bags: 300–500 pcs

Genuine leather crossbody bags: 100–300 pcs

⚠️ Extremely low MOQs often indicate:

Trading companies

Inconsistent quality control

Hidden cost increases later

Quality Control Standards in Crossbody Bag Manufacturing

Reliable manufacturers follow strict QC processes:

- Raw material inspection

- In-line inspection during production

- Final inspection before shipment

Key quality control points include:

- Shoulder strap stitching strength

Edge paint durability

Zipper smoothness

Logo alignment

In real production, strap stitching and edge paint durability are the two most common quality issues we see during inspections.

Common Mistakes When Choosing a Crossbody Bag Manufacturer

Reasons for brand failure typically include:

- Choosing suppliers based on price only

- Ignoring communication quality

- Skipping the sample modification process

- Ignoring the supplier’s export experience

A good manufacturers should like a long-term partners, not just short-term vendor.

How to Evaluate the Right Custom Crossbody Bag Manufacturer

Before placing an order, confirm:

Years of export experience

Main export markets (US, EU, Australia or others )

Sample lead time and revision policy

Transparent pricing structure

How to evaluate manufacturers:

Why Long-Term Brands Work with Specialized Manufacturers

Successful brands:

Establish a consistent product lines

Improve profit margins over time

Reduce quality risks

Working with a specialized custom crossbody bag manufacturer allows brands to focus on marketing and distribution —while ensuring stable and scalable production.

Final Thoughts

Crossbody bags are not a short-term trend. They are a core category for modern accessory brands.

Choosing the right custom crossbody bag manufacturer directly affects:

Product quality

Cost control

Brand reputation

If you are planning to develop or expand a crossbody bag line, selecting the right manufacturing partner will determine your long-term success.

Below are some common questions brands ask when working with a custom crossbody bag manufacturer.

FAQ:Custom Crossbody Bag Manufacturer

A professional custom crossbody bag manufacturer provides end-to-end OEM and ODM services, including bag design support, material sourcing, sample development, bulk production, quality control, packaging and shipment delivery. This allows brands and importers to focus on sales and marketing while production is handled professionally.

sample time about 5-15 days based on style .production time Usually 25–45 days after sample approval.

Yes. Most crossbody bag manufacturers support logo methods, such as embossing, debossing, metal logo plates, silk printing, and woven labels. The manufacturer should recommend the most suitable logo option based on your bag material and target price.

MOQ depends on materials and design complexity.

PU or fabric crossbody bags usually start from 300–500 pcs

Genuine leather crossbody bags often start from 100–300 pcs

A reliable manufacturer will explain MOQ clearly before sampling begins.