In minimalist leather crossbody bag manufacturing is not defined by how simple the design looks, but by how consistently that simplicity can be reproduced at scale.

In today’s highly competitive handbag market , minimalism is no longer a design style, it is an experienced manufacturing concept. Minimalist leather crossbody bag focuses on clean lines, simple hardware, quality materials (leather, durable vegan leather ,microfiber leather), and functional, uncluttered design, featuring essential pockets without excessive embellishments. This means that from the selection of high-quality leather materials to the strict control of production consistency, any minor oversight will directly undermine the value of the brand. At Solton Leather factory, we deeply understand the manufacturing philosophy behind minimalism and are committed to providing outstanding quality that can withstand scrutiny for your OEM or own-brand products.

This guide is written for global brand owners, wholesalers, and purchasing managers to help them develop custom leather crossbody bags for brands while avoiding excessive costs for unnecessary complexity and reducing quality risks associated with mass production.

Whether you’re evaluating OEM minimalist crossbody bag suppliers or considering choosing a private-label leather crossbody bag factory for faster market entry, understanding the differences in manufacturing is crucial before going into production.

What Defines a Reliable Minimalist Leather Crossbody Bag Manufacturer?

In minimalist leather crossbody bag manufacturing, a reliable manufacturer is defined not by how simple the design looks, but by how consistently that simplicity can be reproduced at scale.

From an OEM manufacturing perspective,minimalist design demands more from everything:

- Precision-cut silhouettes with stable structure

- Uniform grain and thickness across each batch

- Simple and high-end hardware (often limited to 1–2 components)

- Smooth edge painting and reinforced high-tension points

- Refined, low-profile branding options ,suitable with private label project.

Minimalist designs more evident demonstration of craftsmanship level. When stitching, leather quality, or edge finishing is inconsistent, defects become immediately visible.

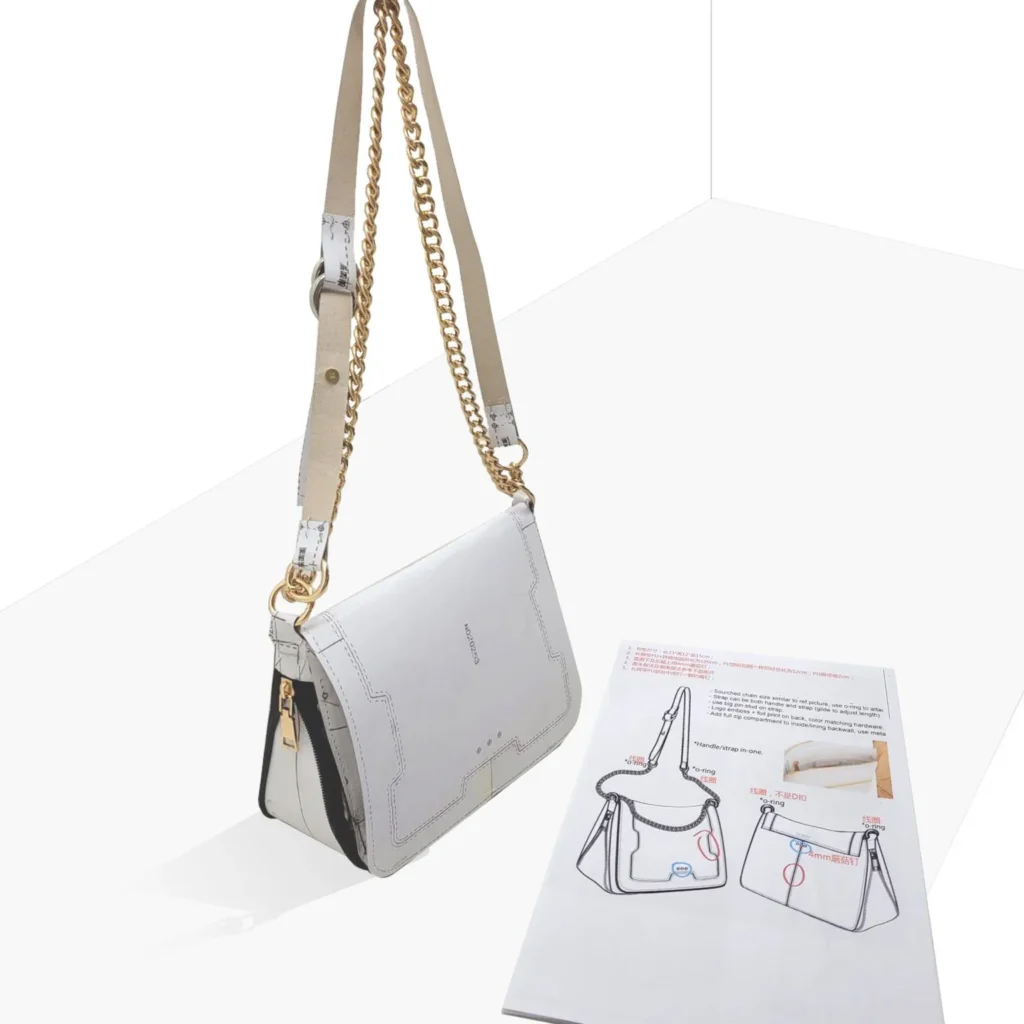

Custom Leather Crossbody Bags for Brands: From Concept to Production

For brands developing custom leather crossbody bags, the process starts long before sampling.

At the OEM stage, the key issue are not about embellishments—they are about intent, utility, and proportion:

Who is the final customer? Daily commuter, travel, or lifestyle fashion?

How much weight will the bag carry?

After using it for a period of time, did the structure remain hard or did it become soft?

Is the bag designed for seasonless carry or trend-based launches?

For brands, minimalist crossbody bags often become core SKUs—not seasonal experiments. That makes early-stage decisions around leather type, strap construction, and internal layout critical for long-term scalability.

custom crossbody bag manufacturer

Who This Minimalist Crossbody Manufacturing Guide Is For

This guide is specifically written for:

Brand founders sourcing high-quality custom leather crossbody bags for brands to launch

Product managers comparing OEM vs private label manufacturing options

Retailers launching minimalist leather collections

Buyers seeking a reliable long-term crossbody bag manufacturing partner

OEM Minimalist Crossbody Bag Supplier: When Full Customization Matters

Working with an OEM minimalist crossbody bag supplier becomes essential when brands require:

Exclusive design or dimensions

Custom-developed leather colors or finishes

Branded hardware or unique strap style to choose

Long-term IP protection and pattern ownership

Unlike ODM or catalog-based production, OEM manufacturing allows brands to fully control how to transform minimalism into functionality

However, OEM minimalist bags are often harder to manufacture than complex-looking styles. The absence of visual elements means the factory must rely on:

Professional tech packs and molds

Stable leather sourcing

Stric control during mass production

This is where experience matters more than equipment.

Private Label Leather Crossbody Bag Factory: A Faster Route to Market

Not every brand needs full OEM from day one.

For startups, retailers, or promotional programs, working with a private label leather crossbody bag factory offers a faster and lower-risk entry point.

Private label production allows brands to:

Use proven minimalist silhouettes

Customize logo, color, and packaging

Launch quickly with lower MOQs

Focus resources on branding and sales channels

This model is particularly effective for:

Gift-with-purchase (GWP) programs

Entry-level collections

Market testing in new regions

The trade-off is exclusivity—but for many brands, speed-to-market outweighs design ownership at early stages.

OEM vs Private Label for Minimalist Crossbody Bags: Which Is Right for Your Brand?

The decision between OEM and private label is strategic, not technical.

OEM provides control unique design but requires higher investment and time.

Private label provides faster market entry by adapting existing designs with your branding

At Solton Leather ,we will accept Choose OEM for exclusive designs & long-term IP, and Private Label/ODM for speed, cost-efficiency, and testing new categories, potentially blending both strategies.

This approach balances margin, speed, and risk—especially in minimalist categories where design lifecycles are longer.

OEM vs Private Label for Minimalist Leather Crossbody Bags

| Factor | OEM Manufacturing | Private Label Manufacturing |

|---|---|---|

| Design Ownership | Brand-owned | Factory-owned |

| Time to Market | Longer (development required) | Faster (ready designs) |

| MOQ | Medium to high | Lower |

| Customization Level | Full | Limited |

| Best For | Core brand products | Market testing & fast launches |

Why Minimalist Leather Crossbody Bags Isn't Easy to Manufacture Than They Look

Minimalism minimalism raises the bar for quality.

The main difficulties lie as following :

Material :Any imperfections in the leather (scratches, inconsistent grain, color flaws) become glaringly obvious, requiring premium, consistent hides.

Assembly and Symmetry:The bag need to be symmetry when assembling the bag various leather piece. For example, the seams on both sides must be perfectly aligned, and the shoulder strap attachment points must be at the same height on both sides.

Interior Compartment:How can you achieve organized storage within a seemingly empty interior, through features like a hidden zippered pocket, an elastic pen holder, or a soft laptop compartment?

Edge Processing:The edges of the leather must be perfectly cut, whether they are sealed finish or oiled edge, must be smooth, flat and have uniform color.

- Hardware Integration: Even minimal hardware, like zippers or clasps, must sit perfectly flush and function flawlessly, requiring precise placement and reinforcement within the leather structure.

Experienced manufacturers address this through:

The factory strictly controls the purchase of materials for each batch.

Used the High Quality hardware ,like zippers , clasps or D ring.

Exquisite craftsmanship control, QC inspection before package

Creating a premium minimalist crossbody bag requires not only clean lines and a sturdy structure but also excellence materials and good craftsmanship skill.

Recommended Leather Types for Minimalist Leather Crossbody Bags

Material choice is critical because minimalist designs expose every surface detail.

| Leather Type | Key Features | Best For |

|---|---|---|

| Saffiano Leather | Scratch-resistant, structured | Urban & professional brands |

| Pebble Leather | Textured, hides wear | Private label programs |

| Smooth / Nappa Leather | Soft, premium feel | Boutique & luxury lines |

| Eco friendly / Vegan Leather | Sustainable, certified | Eco-conscious brands |

OEM Tip: For first orders, structured leathers reduce rejection rates and improve batch consistency.

Key Stages in Minimalist Leather Crossbody Bag Manufacturing

Material selection & leather batch control

Pattern engineering for minimalist silhouettes

Sample approval & tolerance adjustment

Bulk production & inline quality control

Final inspection & export preparation

MOQ, Pricing & Production Timeline (OEM Reference)

Typical production parameters for minimalist leather crossbody bags:

MOQ:

Standard colors: 100 pcs

Custom colors/materials: 300–500 pcs

Sampling: 7–14 days

Mass production: 25-40 days

Ex-factory price range: PU leather :8-15 USD, Genuine leather :15-28 USD based on your style

Low-MOQ options are available for selected designs.

How to Choose the Right Manufacturing Partner for Minimalist Leather Crossbody Bags

Whether you’re looking for a minimalist leather crossbody bag manufacturer for full OEM development or a private label leather crossbody bag factory for faster launches, the right partner should offer:

With flexible MOQs and Cost Transparency

Look for manufacturers experienced with leather handbags and minimalist styles, not just general bag makers.

The sales team demonstrates quick responsiveness and clear communication.

Proven export experience to the US & EU,Southeast Asia,Australia

Select a partner willing to grow with your brand for future success.

FAQ: Minimalist Leather Crossbody Bag Manufacturing

Manufacturers use various materials, including genuine leather (full-grain, top-grain, and suede), vegan or faux leather, and microfiber leather.

For businesses looking to order custom crossbody bags, industry standards for genuine leather typically range from 100-200 pieces per style/color, while synthetic materials usually require higher MOQs (300+ pieces).

Logo debossing, hot stamping, and Pantone color matching are commonly supported.

Minimalist leather crossbody bag manufacturing refers to a production process focused on clean lines, simple shapes, quality materials (like genuine leather or pu leather), and functional elegance. Because there are fewer decorative elements, quality control in leather selection, pattern accuracy, stitching, and edge finishing becomes more critical than in complex bag designs.

Sampling usually takes 7 to 14 days, while bulk minimalist leather crossbody bag manufacturing generally requires 25 to 40 days, depending on order volume, material availability, and quality control requirements

Start Your Minimalist Leather Crossbody Bag Project

Minimalist leather crossbody bags are often long-term, repeat SKUs for brands—not one-off products.

If you’re evaluating OEM development or private label production, working with an experienced manufacturing partner can significantly reduce sourcing risk and long-term cost.

Contact our team to discuss your minimalist crossbody bag project, material options, and MOQ feasibility.